DESCRIPTION

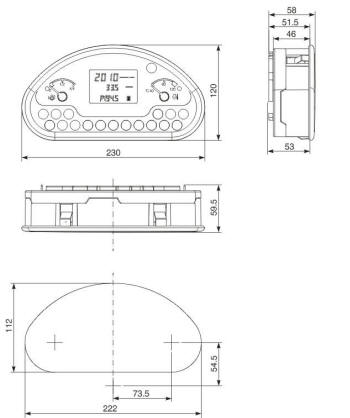

Thor is a very compact and features dual technology (analog and digital)

fully managed by microprocessors. This allows a prompt response and

easy reading of analogic values together with a wide matrix display.

A great number of warning LEDs give clear and immediate information

to the user. This display, made with transflective technology, provides an

excellent reading in any light condition also thanks to Backlight feature.

Display connection for Key Pad (option) available and allows advanced

functions, present in programmed menus.

USAGE

This instrument has been studied to match highest electric traction vehicles'

requirements, both for internal or external usage such as: fork lifts for

material handling, construction machinery, sweepers and cleaning vehicles,

golf cars as well as small electrical cars.

It also particularly suits hire service requirements by managing appropriate

maintenance scheduling.

FUNCTIONS

N 2-

ANALOGIC GAUGES WITH 90 BACKLIGHT FOR AN PROMPT READING OF ALL MAIN VARIATIONS

OF

TRACTION (BATTERY STATE AND TRACTION SYSTEM TEMPERATURE)

N 21- PROGRAMMABLE WARNING LEDS. N 16 OF THEM DIRECTLY FROM MICROPROCESSOR AND

REMAINING

5 CONNECTED DIRECTLY TO INPUTS ON THE CONNECTOR. MICROPROCESSOR MANAGEMENT

ENABLES

TO SET PARTICULAR PERFORMANCES TO EACH WARNING LED SUCH AS FLASHING RATE,

TIMING OR ACTIVATION OF A BUILT-IN BUZZER AT SAME TIME.

EXTERNAL (KEY PAD) CONFIGURATION IS OPTION AND ALLOWS SIMPLE AND CLEAR

SCROLLING THROUGH

ADVANCED MENUS SPECIALLY STUDIED FOR SERVICE, SET-UP AND CUSTOMIZED FEATURES.

Large matrix display gives easy

parameter reading with wide angle vision

and in any environmental light condition.

This display in basic configuration, allows constant, both numeric and

bargraph reading of a range of parameters with complete monitoring

of vehicle's functions. A special Area called Message Center shows the user

eventual warning or service messages.

In particular conditions such as in FAILURE conditions, the whole display

area can be used to give exact indications and eventual instructions to the

user about correct operation activities.

Advanced display design is particularly useful to easily manage typical

maintenance schedules for hired vehicles as well as warranty and leasing

plans.

This instrument is fully custom programmable by using an external (Key Pad)

supplied separately on demand. The parameters required by user, can be

customized and protected by appropriate passwords.

All important data are stored in non volatile (EEPROM) memory, in order to

be

available even when battery is disconnected.

Any vehicle and cable system can be connected thanks to a great connection

flexibility of the instrument. A 36 pole built-in connector allows

instrument

setting both for traditional harness systems as well as CAN BUS multiplex. |

|

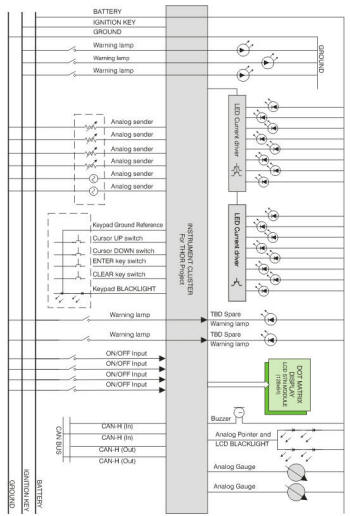

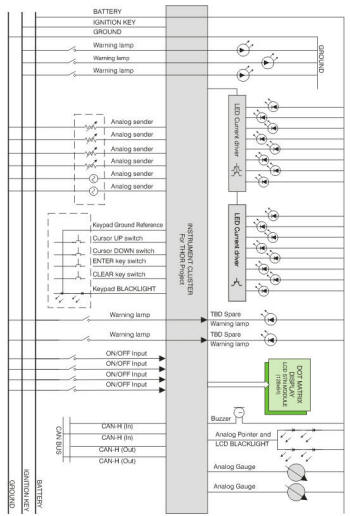

INTERCONNECTION

AND BLOCK SCHEMA

(2) Warning Lamp Inputs (switched to

Ground)

(3) Warning Lamp Inputs (switched to Battery reference)

(4) Analog input for Sensor sender

(2) Frequency Input for Vehicle and Engine speed

(8) ON/Off Microprocessor Input (switched to Ground)

CAN BUS Interface

External Navigation Keypad Interface

Serial Port for Programming and Maintenance

|

SPECIFICATION

Operating 12 Volt Nominal(10 -16 Volt)

Voltage 24-48 Volt Nominal(18 -60 Volt)

Operating

Temperature -20°C +65°C

Storage Temperature -40°C +85°C

Sealing IP66 (Front Face)

IP40 (Rear)

EMC 95/CEE E mark according to

Reg 10 on Customer request

|